Our Product

Home >> Our Product

CP130

A Thermoplastic Multipolyamide

The thermoplastic polyamide for tough, high elongation, soluble and adhesive or flexibiliser applications.

CP 130 is a multipolyamide product from the Chennai Polychemicals Pvt. Ltd., manufacturer of bulk drugs since 1990 which has clientele across India.CP 130 is a thermoplastic multipolyamide of lower melting range which exhibits excellent toughness, higher elongation and easy solubility in alcoholic solvents and their blends.

This multipolymer thermoplastic polyamide also has a special property of crosslinking with a thermosetting resin which makes it suitable as ahot melt adhesive, solvent based adhesive or merely as a flexibiliser that finds a variety of end uses.

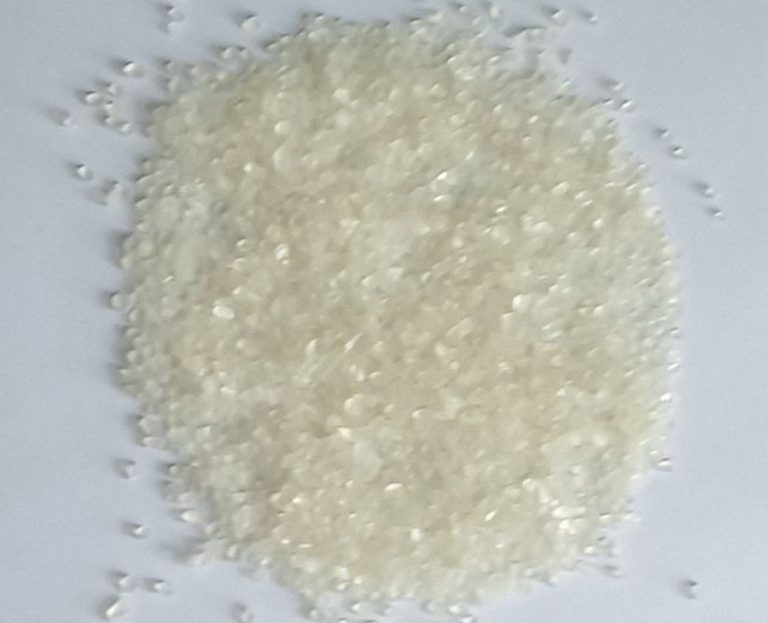

CP 130 is supplied in 25 kg HDPE lined kraft paper bags and in the form of clear, uniform chips.It is tough in dry condition but with continuous exposure to atmosphere makes it soft and flexibledue to moisture absorption. Excellent toughness, higher elongation and easy solubility in alcoholic solvents and their blends make it useful for wide variety such as Hot-Melt Adhesives in Nylon Laminated Transmission Belts, Tapes, etc., in Footwear Industry for different component joining, in Textile Industry for Sewing Thread Bonding, PVC Cloth Coating, Fabric Dip Coating, Leather Coating and in Electrical industry for Cable and Wire Sheathing.

Physical Properties

The product is a mutipolymer thermoplastic polyamide, available as clear uniform 2mm chips with a bulk density of 1.11g/cc. Water Absorption at max. 23°C is in the range of 10-12% and Moisture regains is in the range of 2.5-3.5% after 24 hrs (ASTM test method D570). The usual polyamide viscosity number measured in 95% sulfuricacid, 0.5 g/100ml is in the range of 2.5-2.7. Density determined ASTM test method D 792 is 1.11g/cc. The product melts at the range of 160-170°C (ASTM test method D2117) and the glass transition temperature of the dry material is about 40°C.

Mechanical Properties

CP130 is mainly applied assolution on leather, nylon and or substrate. The properties of the adhesive solution is directly proportional to the adhesive solution components ratio, making process, base material and application technique. The tensile strength is 49.7 Mpa and Elongation is 300% under the test method of ASTM D 638. The impact strength is 4.9 Kg cm/cm under the test method of ASTM D 256A.

Storage

CP 130 thermoplastic polyamide can absorb moisture from the atmosphere and should be carefully packed or sealed and stored in dry conditions without exposure to moisture. The product can be stored successfully atleast for a year provided the precautionary measures are taken.

Preparation of Adhesive Coating

Adhesive solutions of CP 130 thermoplastic polyamide are generally prepared both at room temperature and may need to warm up to 25-40mixing of the solvent components. A variety of alcoholic solvents and their blends can be used. The examples are

- 80% Methanol + 20% Water

- 70% Methanol + 20% Benzene + 10% Water

- 70% Methanol + 20% Methylene Dichloride + 10% Water

- 100% Methanol

The general guideline for preparing the Adhesive Coating involves adding 10-20% of CP 130 to any one of the solvent mixture listed above (A,B,C or D) with stirring in a high speed Agitator or Tumbler Mixer. The mixture is stirred for 2-6 hours until the solution becomes uniform and ready for application.kl;moo

Industrial Applications and Advantages

CP 130 thermoplastic polyamide are ready to use with minimal preprocessing / preparation and used across industry verticals because of its excellent toughness, higher elongation and easy solubility in variety of solvent mixtures. The Adhesive solution –

• is easy to prepare (even at room temperature)

• has excellent mechanical and physical properties

• has proven track record of quality in products across Footwear industry, Electrical industry, transmission belt manufacturers, fabric and accessories industry

• having satisfied clientele over 30+ years

Safety Information

Basic preventive measures generally applicable to chemicals apply as per the specific industry guidelines like eye protection, skin protection and proper ventilation to avoid breathing related complications. There are no specific health hazard reported and or recorded till date over 30 years with proper usage and handling of CP 130 thermoplastic polyamide.

- Hazardous Ingredients

This is a polymeric material. All components are enclosed in the polymer system, and hence there is no possibility of exposure at present under normal conditions of processing and handling.

- Fire & Explosion Data

LEL: N/A; UEL: N/A

Extinguishing Media – Water, Carbon dioxide, Foam, Dry Chemical Treat as Class B Fire

- Health Hazard Data

Inhalation: Expose to fresh air – if fever or flu-like symptoms are present, refer to a physician for treatment

Skin or Eye Contact: Hot melted cast Nylon will cause Thermal burns with Skin contact. Cool rapidly with cold water and do not attempt to peel nylon from the skin. Obtain medical attention for thermal burn. Burning sensation or irritation will occur with eye contact. Flush with water.

- Reactivity Data

Stability: Stable

Incompatibility (Materials to avoid): Strong acids and strong oxidizing agents

- Accidental Spill or Leak

Vacuum cleaning or wet sweeping to minimize dust exposure

Waste Disposal Method: Incineration or Land fill in compliance with federal, state and local regulations.